CAPABILITIES

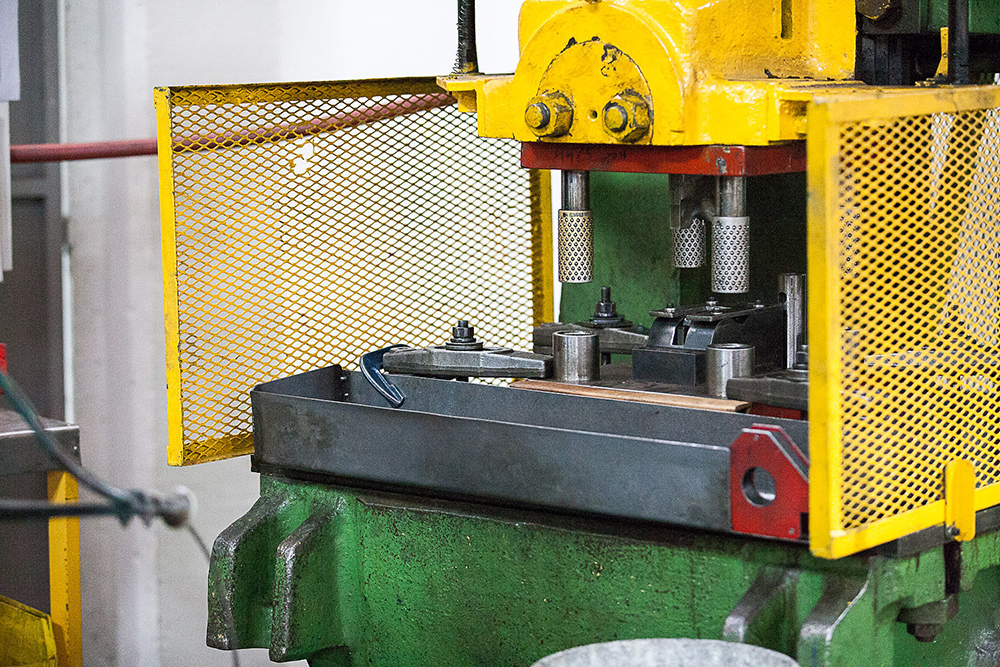

Progressive stamping is a metalworking process that encompasses punching, coining, bending and several other ways of modifying sheet metal raw material. We then combine these processes using an automatic manufacturing feeding system.

Stamping operations include many secondary processes such as bending, coining, piercing and forming of sheet metal, tubes and rod products. We use both mechanical and hydraulic presses, depending on part shape and specifications.